故障解析(FA)

主な必要性能

故障解析における主なプロセス

-

-

- リーク測定、オープン/ショート検出による電気的な故障診断

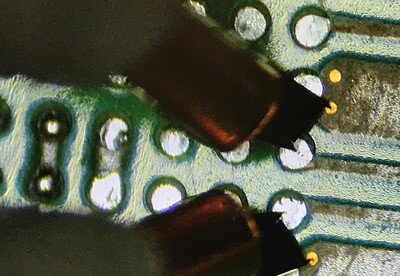

- “mini pads”上に高インピーダンスPicoprobeを使用したノードプロービング

- 複雑なICに幾千もある中から、最適な“mini pads”を見つけるのは非常に困難

- ICの駆動をプローブカードで行い、プローブを用いてマイクロプロービングを同時に行う

- このようなプローブカードは通常特注で作成します。プローブカードには能動素子が搭載されており、プローブカードの長さは非常に長い場合もあります。(13インチ以上)

- ホットスポットおよびエミッション解析による故障個所の特定

- レーザーによる、パッシベーションの削除、メタル層や線の切断

- MEMSデバイスの故障解析にはオンウエハでのマイクロモーション解析も有効

- ハイパワーデバイスにおける10 kV テスト環境での故障解析

- 顕微鏡には高解像度のものが必要

-

MPIのソリューション

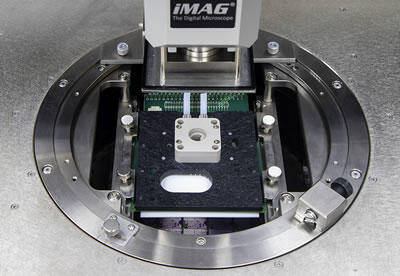

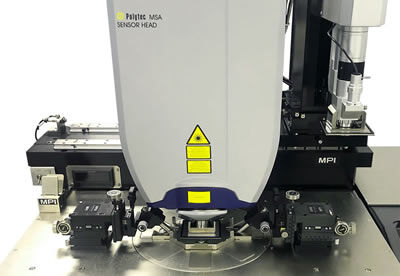

MPIの故障解析用プローバ・システムは高精度な測定結果を短時間に導き出すための必要条件を備えています。剛性の高い 研究開発用プローバ・システム および非常に精度の高いポジショナは電気的故障解析、故障場所の特定、デバッギングに最適なソリューションを提供します。優れた防振機構や、広角ズームおよび高倍率顕微鏡により、1ミクロンまでの構造にプロービングできます。

MPI TS3000 プローバ・システムはプローブカードとポジショナを同時に使える構造になっていますので、-60℃においても、DUTをプローブカードで駆動しながら デバイスの信号をプローブで測定することが可能です。

プラテンとチャックの距離が短いのでPicoprobeを用いた測定が容易にできます。

ユニークなMPIレーザーカッタシステム、LCS-635 は信頼できる故障解析および、1064nm、532nm、355nmまたは266nmの波長に基づいて、数種類の半導体材料、メタル層の除去が可能です。

MPI の研究開発用プローバ・システムは、浜松ホトニクスなどのエミッション顕微鏡と組みあわせることにより、IC故障の解析、場所の特定が可能になります。さらに TS150/TS200-HP プローバ・システムは10kVおよび600Aまでの ハイパワーデバイス の故障解析に適しています。